Different Types of valves and their Importance!

Valves are considered to be simple devices which are used to control the flow of fluid by obstructing the passageway or the pipes. These can be found in many places where the fluids flow and it can include your bathroom as well specifically faucet. Water flows out when turning the handle, turn it back and water will stops flowing. Let’s know about different types of valves:

The main function of Slide gate valves is to keep the pressure of the water under control. Due to continuous water pressure there is more chances of wear and tear of any part of the valves increases. As such, it is generally suggested that the valves need to be thoroughly checked before only for trouble free and smooth functioning. However, due to one reason or any other if the valve get damaged it should to be replaced on urgent basis so that the risk factor of major problem can be minimize.

Knife gate valves are basically made for on and off and isolation services in the systems with high content of suspended solids. These valves are especially important for handling viscous, corrosive, slurry, and the abrasive media. The valves provide a minimised pressure drop in the fully open position, these valves are easy to actuate, the weight is relatively low and these are cost effective.

Globe Valves are spherical in shape as per the name. These valves offer greater exactness than the other types of valves when it comes to the regulating flow. These are used in applications where the flow needs to be finely tuned. They have a structure of plate with a hole in it, and a disk or a plug wholly or partially fits into the hole, slowing and stopping flow.

Swing check valves are in less used when it is compared with the other types of widely used valves. Under the reverse flow conditions this swing check is held firmly against the valve seat and preventing system losses. These valves are good for keeping the pump aware when the power is gone. They help the water to flow back from the filter into the pond. These can be buy in many sizes and in different types.

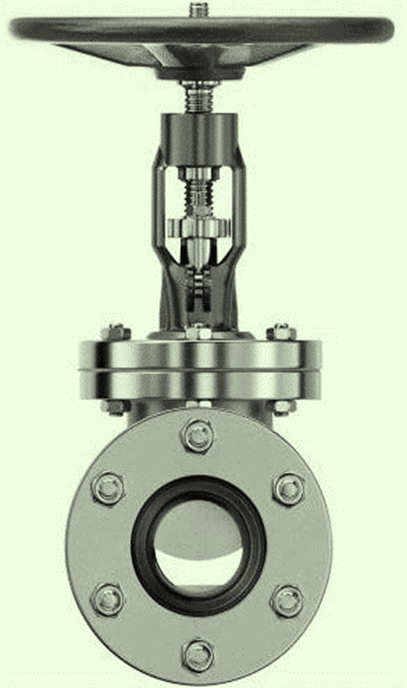

A bellow seal valve has a solid structure and is the one kind of control valve which help to balance the pressure. To ignore the leakage of the valve stem, valve adopts the structure with the bellows instead of stuffing boxes normally used for the ordinary valve or the structure with both stuffing and bellows boxes. It is basically suitable for the pipelines of explosive and hazardous media, steam and flammable. Moreover, because of bellow's properties of aging and deformation resistance, the bellow seal valve overcomes the most common latent defects, which includes temperature sensitivity and the aging of the stuffing box, and these defects are taken care by the valve which are sealed by packing. It is operated as an obstruction between the fluids and the air. At the same time, the valve can also prevent the fluids leaking to the air and guarantee on zero leakage of pipelines.

Comments

Post a Comment