Industrial valves and its types

Industrial Valves

Industrial valves are a large set of manufacturers where mechanical devices are set up as regulators of gaseous, liquid, and other systems. These are called valves. For example, gate, diaphragm, plug, and pressure reliefs control different types of flow by its operated machines. There are large bulk of Industrial Valvelocated in India with the enormous type of block and blood valves that controls blood flo w and play a major role in petrochemical sectors. Like instrumentation valves and pressure valves, other types of valves are also widely available in the country.

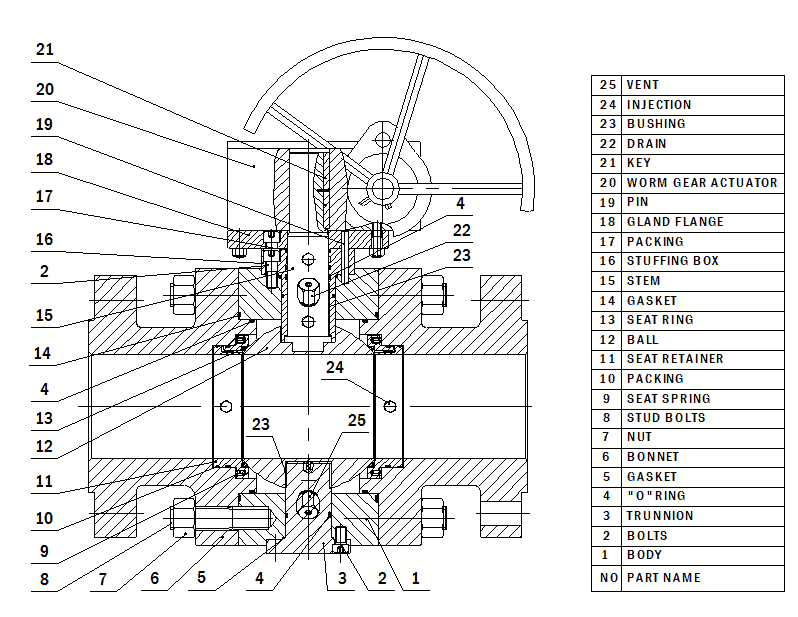

Trunnion Ball Valve

Trunnion ball valveis another enormous valve invention in the industry which use to control flow by its hollow shaped quarter ball in front of the valve mechanism.

- How it works-

- The ball in the machine is linked to the stem (operator or long support on the top of the machine), and it is also connected to the trunnion of the machine, which is in a hollow cylindrical shape.

- When the machines are on, the ball connected to both things rotates in its position.

- The rotation of the ball in the machine works as a principles body and generates its own functions.

- For what purposes they are used-

- The trunnion ball valves are used for on-off controls, which are gate valves and globe valves.

- It is also used for control application of machines

- To control pressure extensively.

- Advantages of Trunnion Ball Valve are

- This machine eases the steps of operation.

- Presents better performance and services as it minimizes the fluids.

- Either the pressure is low or high, the trunnion ball valve can perform protectively and efficiently.

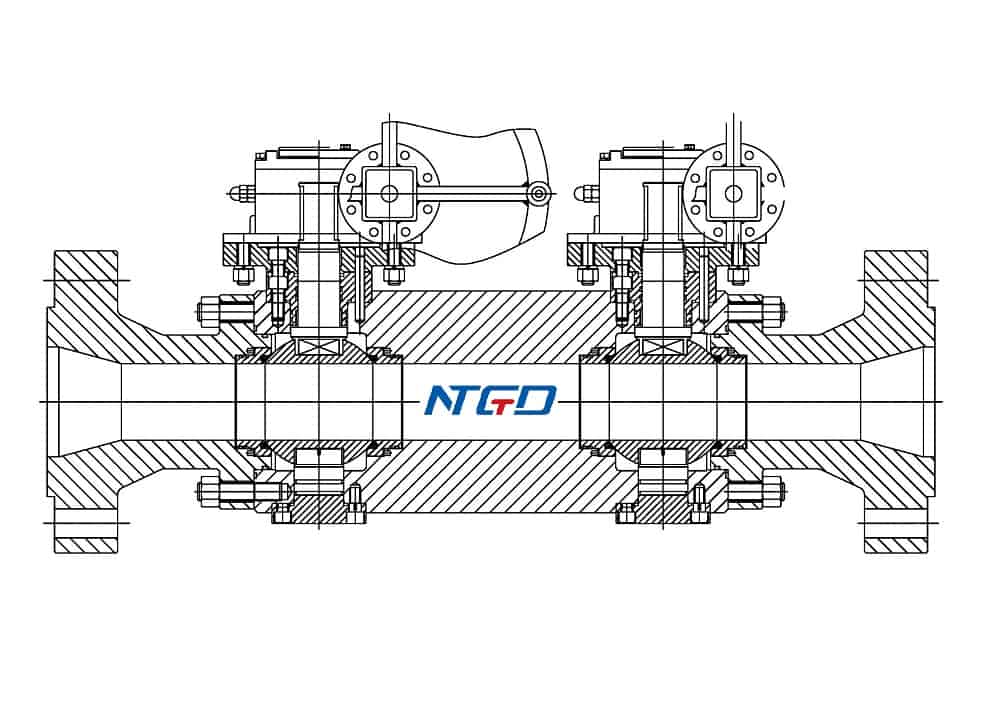

Double Block and Bleed Valves (DBB)

The Double block and bleed valve are two in one automated machine set up in the maximum number of industries. This machine blocks the flow of fluid by its needle and ball valves activated in the machine.

- For what purposes they are used-

- To stop or pause the flow of fluid from where the work is being done.

- Used for petrochemical and valves industries

- How it works-

- The two valves in the machine should be closed, and the bleeder would be opened to start its functions.

- Before any pressure of downstream valves, the first half of the valves will drain the flow.

- Advantages of DBB

- Its uses and functions can be compared to a high-level isolation machine.

- This machine is compactum in the valve industry.

- Personal advantages are- it reduces weight, cost, and high exposure.

- It is a time-saving machine as it works fast.

To be specific, these valves machines efficiently stop gas or liquid flow with high capacity, functions, and stems.

In conclusion, these valve machines are the ultimate stoppage to any form of fluid, liquid, or gas opted in an industry. The trunnion valve machine costs approx. 15,000 and Double block and blood valves cost 1,200 to 1,500 approx. These machines are affordable, and anyone can start small scale industries with the valves machines, which are beneficial and on-demand machines for industries in today’s rate.

Well-structured and easy to follow—nicely done.

ReplyDeleteCheck Valve Manufacturers in China